| MACHINE MODEL | 1575B (OTHER SIZE TO BE SPECIFIED) |

|---|---|

| Raw Material Width | 1750mm (Other size to be specified) |

| Finished Roll Diameter | φ90- φ140mm (Other size to be specified) |

| Finished Roll Core Diameter | φ38- φ48mm |

| Raw Material Diameter | ≤ 1100mm (Other size to be specified) |

| Raw Material Core Diameter | φ76mm (Other size to be specified) |

| Perforation Pitch | 4 pieces of Anvil blades(115mm,230mm) Other size to be specified |

| Machine Speed | 0-180m/min |

| Programming Controller | PLC (Delta) |

| Unwinding Unit | 1-3ply (Other size to be specified) |

| Air-System | 0.5-0.8MPA (provide by user themselves) |

| Power | 18kw |

| Dimensions | 10000x3000x2000mm (LxWxH) |

| Machine Weight | 12 Tons ( All machine 40mm Wallboard type insititutions) |

| Basis Weight | 1-3ply, 14-30gsm |

| Edge Embossing Unit | Steel to steel, Independent pneumatic control |

| Embossing Unit | Big roll steel to steel embossing |

| Voltage | 380V,50Hz |

| MODEL | 150 LOG SAW MACHINE (DOUBLE CHANNEL) |

|---|---|

| Jumbo Roll Max Width | 1750mm(Other size can be specified) |

| Jumbo Roll Diameter | φ100- φ115mm (Other size to be specified) |

| Design Speed | 150 cut/min |

| Stable Speed | 100 cut/min |

| Grinding System | Pneumatic Sharpen, grinding time can be set |

| Driving System | Delta Servo Motor |

| Power | 11kw |

| Dimension | 6500x2500x2000mm(Other size to be specified) |

| Blade Diameter | φ610x4.7mm |

| Voltage | 380V,50Hz |

| Weight | about 4.5 Tons |

| MODEL | QWZ450 |

|---|---|

| Packing speed | 50-80bags/min |

| Film width range | 300 -400mm |

| Dia. of paper roll (Finished bag size) | 100 -130mm |

| Bag length (Finished bag size) | 70 -400mm (adjustable) |

| General power | 3.75kw |

| Motor power | 1.0;0.75kw |

| Machine weight | 1200kg |

| Outer dimensions | 6400x965 x 1700mm |

| Power supply type | 220V 50Hz |

| Packing film | CPP, OPP,etc. |

| MODEL | SEMI-AUTO MUILTI ROLLS PACKING MACHINE |

|---|---|

| Power | 380V 50HZ |

| Main circuit power | 0.74KW |

| Sealing Sealing transformer power | 0.45KW |

| Total Power | 1.19KW |

| Pressure | 0.4 --- 0.5MPA |

| Machine size | 6.5X1.2X1.2M |

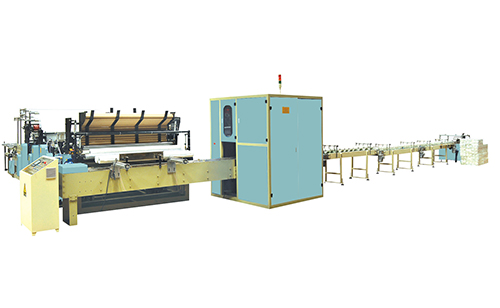

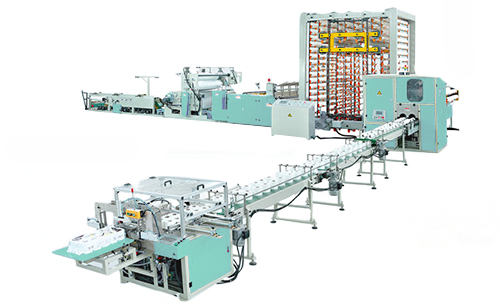

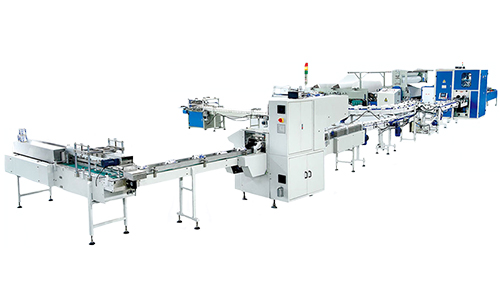

Introduction:

1. This production line are consist of the following FOUR machines:

– Fully Automatic Toilet Paper Rewinding Machine,

– Automatic Log Saw Cutting Machine,

– Automatic Single Toilet Roll Packing Machine.

– Semi-Automatic Multi Toilet Rolls Packing Machine.

2. It can automatic loading material to finish cutting and packing output.

3. The whole production line are driven automatically by mechanical, It can realize cooperate smoothly and stable performance.

4. This production line will help you save lobor cost and reduce labor intensity and improve production efficiency.

How to Select a Suitable Jumbo Roll Tissue Making Line ?

1). The paper which you want to produce,

2). The Raw Material which you will use, (Pulp Board,Waste Paper, Mix pulp,etc.)

3). The capacity which you want to produce per day,

4). The Paper Width which you require to make,

5). The basis weight of paper which you require to have, etc.

How to select the RIGHT machines ?

Profession Suggestion will be supplied by our Sales Manager & Engineers according to your real situation. We will supply the Right Machines depend on Your Budget,Your Local Suppiler of Jumbo Roll,Your Production Capacity,Your Market Demands,etc.

How many years warranty of the machines ?

All our products will have ONE year guarantee and we will continue to offer advice and spare parts after this period. Standard spare parts and accessories with our machine will be supplied together in wooden case when shipment.

What are the payment terms ?

30% as downpayment by T/T in advance, 70% balance amount by T/T before shipment is our Standard Payment Terms to ALL of our customers in different countries. Irrevocable letter of credit at sight will be considered according to some countries special situation.

How to install & operate our machines ?

Enough photos, VCD and Operation Manual will be supplied together with our machines when shipment. It will show you how to operate this machine.Either of technicians learning at our factory or teaching at your local country is acceptable by our company. ALL these charges will be born by the end-user, such as: visa fee, return air-tickets, accommodation, food and also installation fees,etc.

How to guarantee quality of our machines ?

ALL machines will be tested and have trial production in our factory before leaving our factory and they are shipped out only after customers are satisfied with them. Customers can send your technicians or the Third party inspection agency to our factory to check and accept machines before delivery.

How long does it take for customers to receive our machines ?

As usual,It will take us about 45-60 days to manufacture the new machines after receiving 30% downpayment from customers.

It will take about 7 days for export formality in China.

It will take about 10-30 days for sea transportation.

The average time required is between 50 -90 days depending on the type of machinery being procured.

2016-08-19

2016-08-19

2016-08-19

2016-08-17